The new AS Latvijas Finieris veneer plant in Kuldīga – award winner of the competition “Sustainability in Architecture, Construction, Design in the Baltic States 2024”

09.09.2024

The Building Design and Construction Council’s international competition “Sustainability in Architecture, Construction, Design in the Baltic States 2024” has concluded and the winners were announced on 5 September. In the nomination “Most Sustainable Project” in the category “New Construction”, the third-place award was given to AS Latvijas Finieris for the design of the new veneer production plant “Kuldīga fabrika”. The international jury evaluated the use of wooden structures, as well as the technological process and equipment used.

“Sustainable thinking has been an integral part of operations and culture of Latvijas Finieris for decades, and we strive to improve it continuously. We are pleased that an international jury has appreciated the Group’s achievements at the Kuldīga site, in cooperation with AS UPB, in practice and not just in words, we’ve implemented and demonstrated a sustainable approach.”

Aigars Veitmans, Member of the Management Board of AS Latvijas Finieris

The “Kuldīga Fabrika” production facility, which will open in June 2024, was built on a property the company acquired more than 10 years ago, when it was a degraded, unmanaged site with an unfinished brick factory that was once built but never put into operation and stood abandoned for a long time.

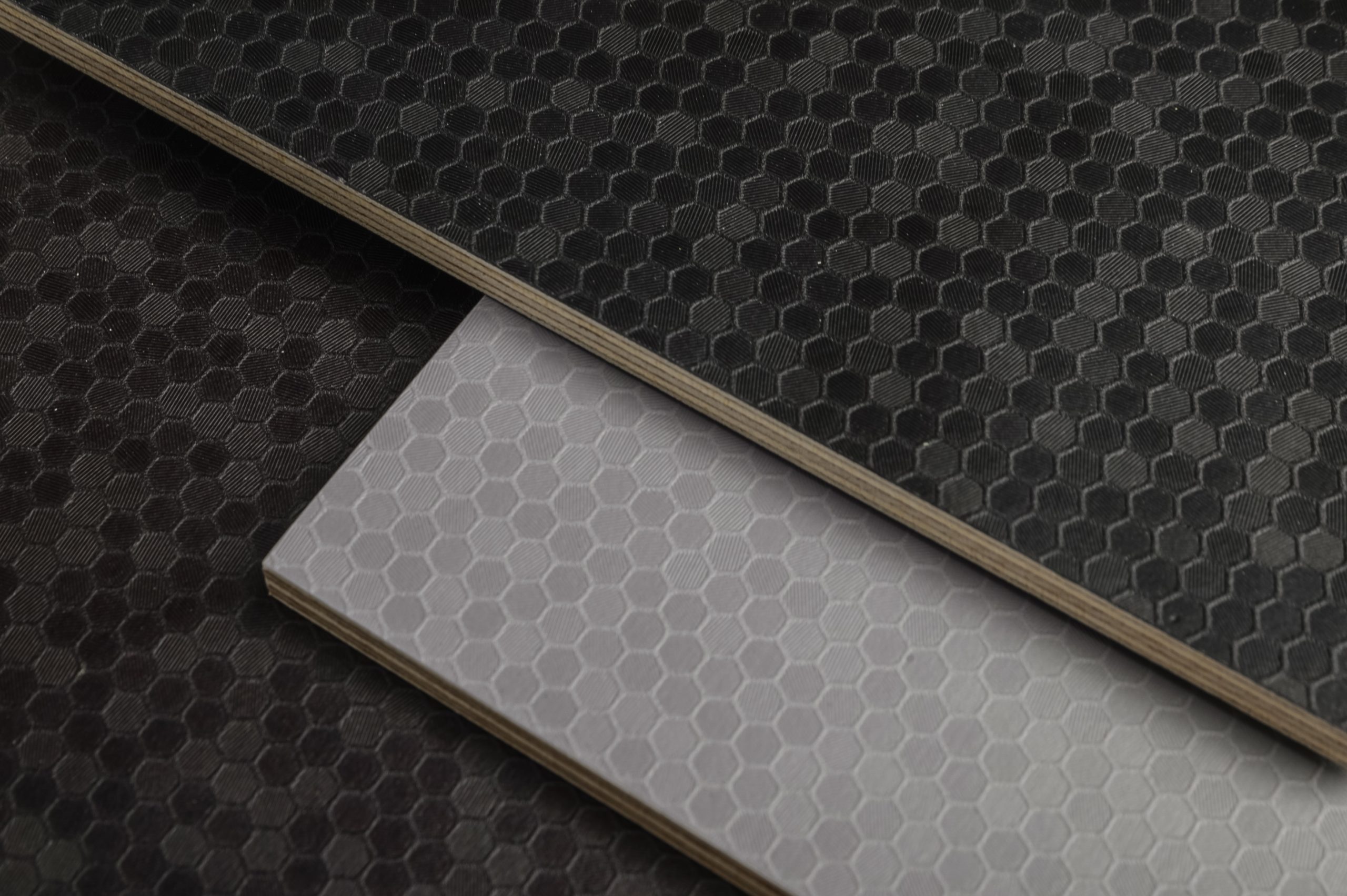

“Kuldīga Fabrika” is equipped with a unique technology that enables the maximum possible veneer yield to be obtained from each birch log. The plant’s unique facility is therefore a major milestone in wood processing, ensuring that thin-wood timber, previously mainly exported to Scandinavia to produce pulp or be otherwise processed, can be used to its full potential in higher value-added birch wood products.

A compact veneer log hydrothermal treatment chamber, one of a kind in Latvia, has also been installed at the plant, where logs are thermally prepared for peeling using the steam method. Thanks to recirculation, it ensures significantly lower water consumption, so only a small part of the water used in the treatment process will end up in the pre-treatment facilities and the centralised wastewater collection system.” The chamber is operated using water from an artesian borehole in the production area. The wastewater from the production process is treated in a suspended solids filter and reused in a sprinkler system to improve the quality of the wood.

A sustainable approach was also implemented in the construction process of the plant building, using glued wooden structures that accumulate CO2. The building meets the requirements of a nearly zero energy building. To improve energy efficiency, solar panels have been installed on the roof of the building. An electric car charging point and bicycle storage have been set up next to the building’s household block.

The design of “Kuldīga Fabrika” focuses on the well-being of workers, creating a pleasant and safe working environment. The lounge and changing room area is also built with wooden structures and finished with Latvian-made wooden interior details and furniture systems, creating a cosy atmosphere and consistently following the working environment quality standards set by Latvijas Finieris.

The aim of the competition “Sustainability in Architecture, Construction, Design in the Baltic States 2024” is to promote the idea of sustainable construction, architecture and design and to educate the public, to highlight best practices, to share information on success factors of such projects, to draw attention to the available resources in the creation of sustainable buildings or in the woodworking or other technologies used in production plants, to gather experience and ideas on the development and conditions of sustainable buildings, production technologies and urban environments in the Baltics.

News category:

Achievements Heavy Building Investment Kuldīgas fabrika Light Building Sustainability