Efficiency as the basis of our development

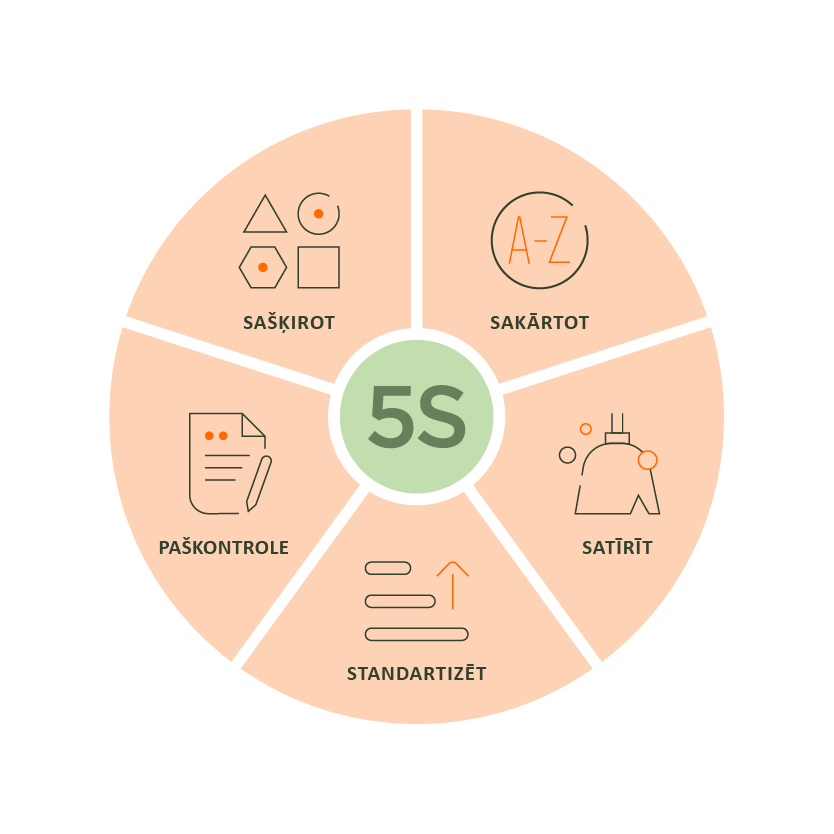

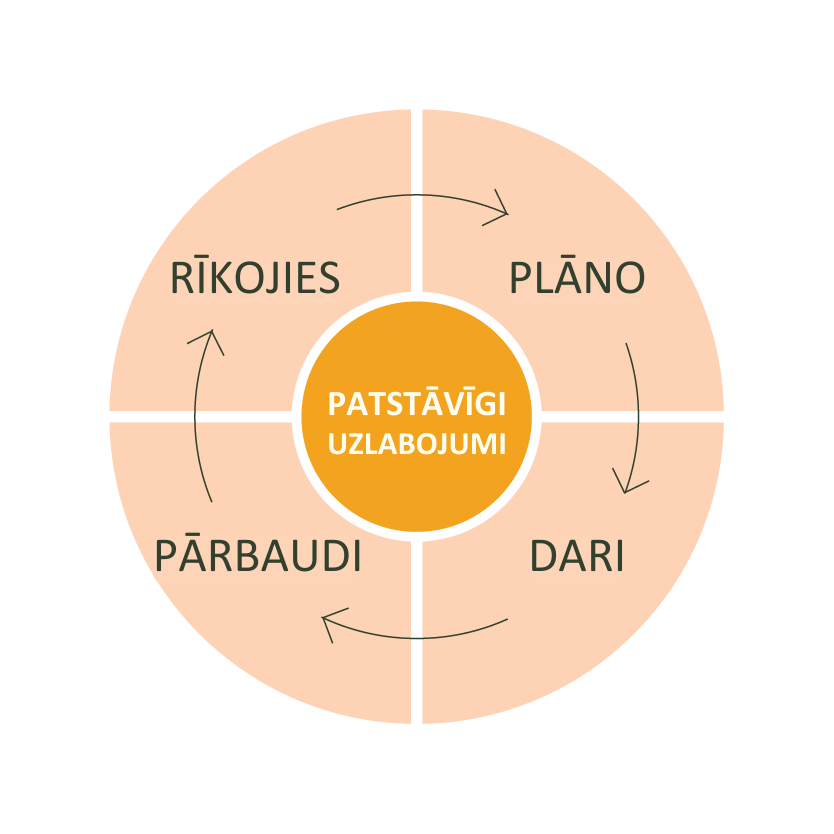

On a day-to-day basis, we achieve efficiency gains through a combination of process automation and mechanisation, energy efficiency, and measures to reduce downtime and improve work efficiency.

On a day-to-day basis, we achieve efficiency gains through a combination of process automation and mechanisation, energy efficiency, and measures to reduce downtime and improve work efficiency.

A fossil-free future

85%

we acquire energy from renewable sources, and we aim to increase this share. Our belief is that unused energy is the cheapest and at the same time the most environmentally friendly, which is why we focus on the efficient use of energy resources in our Energy Policy.

Electricity

The sustainable origin of the electricity consumed in the Group’s Latvian factories is confirmed by the “Powered by Green” certificate issued by Latvenergo. We are gradually taking steps in the self-generation of electricity – solar panel parks have been installed at the Likmere factory and the associated company SIA Troja.

Thermal energy

In birch plywood production, heat energy is mainly used for the hydrothermal treatment of the logs and drying of veneer. More than 20 years ago, we took the decision to phase out the use of natural gas and have switched to renewable wood fuels, including by-products from the plywood production process where it is rational to do so.

Reuse of water

In birch plywood production, we use water in the hydrothermal treatment of veneer plywood, in the production of synthetic resins, and in the cooling and maintenance of equipment. Our technical solutions allow us to reuse most of the water, which significantly reduces the first consumption, and we clean the used water in flotation plants.

Reduced waste

Our aim is to minimise the amount of waste generated in our production processes, but it is impossible to avoid it. This is why we are a part of the circular economy value chain and carefully sort waste at all our plants, wherever possible diverting it for reuse or recycling to obtain valuable raw materials.