Less is more

Whether in terms of GHG emissions and waste, or resource and energy consumption, we are continuously improving the efficiency of our production processes to reduce our impact on the environment.

Whether in terms of GHG emissions and waste, or resource and energy consumption, we are continuously improving the efficiency of our production processes to reduce our impact on the environment.

We also follow the guiding principles of the continuous development environmental management standards at all Group factories, which ensure the progressive reduction of environmental impacts. In recent years, we have started to pay more attention to the processes outside our factories, also analysing the environmental impact in the life cycle and supply chains of our products.

To understand what ambitious steps we can take to mitigate climate change in the future, we regularly calculate our GHG emissions.

Adapting the globally used Greenhouse Gas Protocol (GHGP) calculation, we get a comprehensive picture of the Group’s atmospheric emissions, enabling us to identify the most significant sources of environmental impacts throughout the supply chain and production phases.

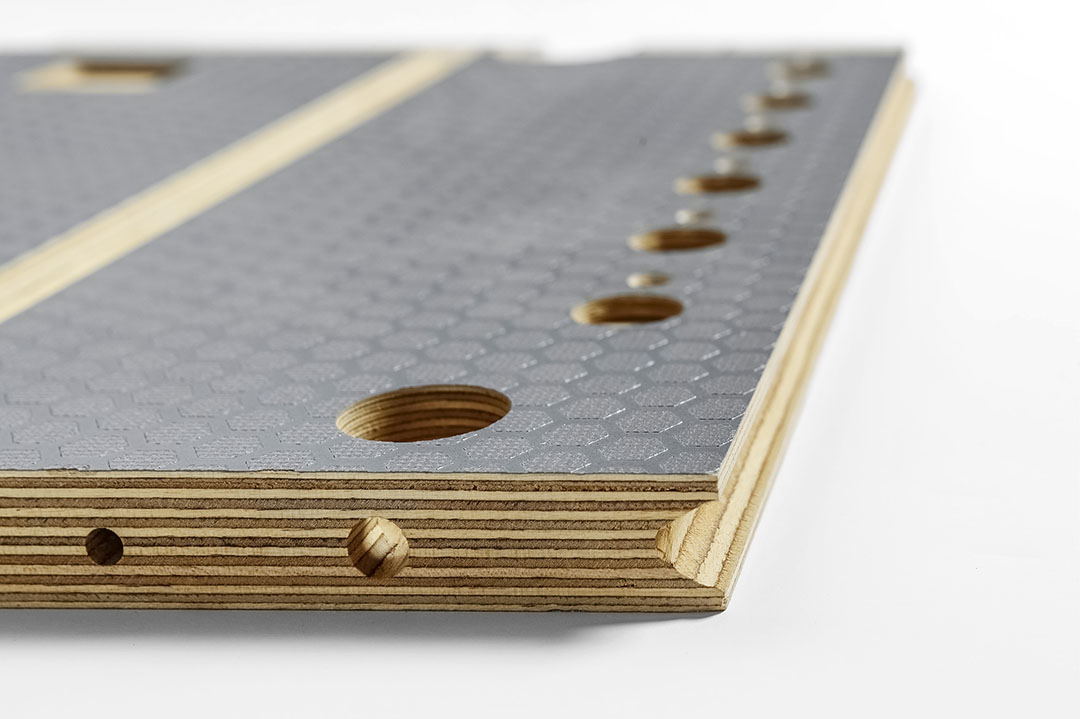

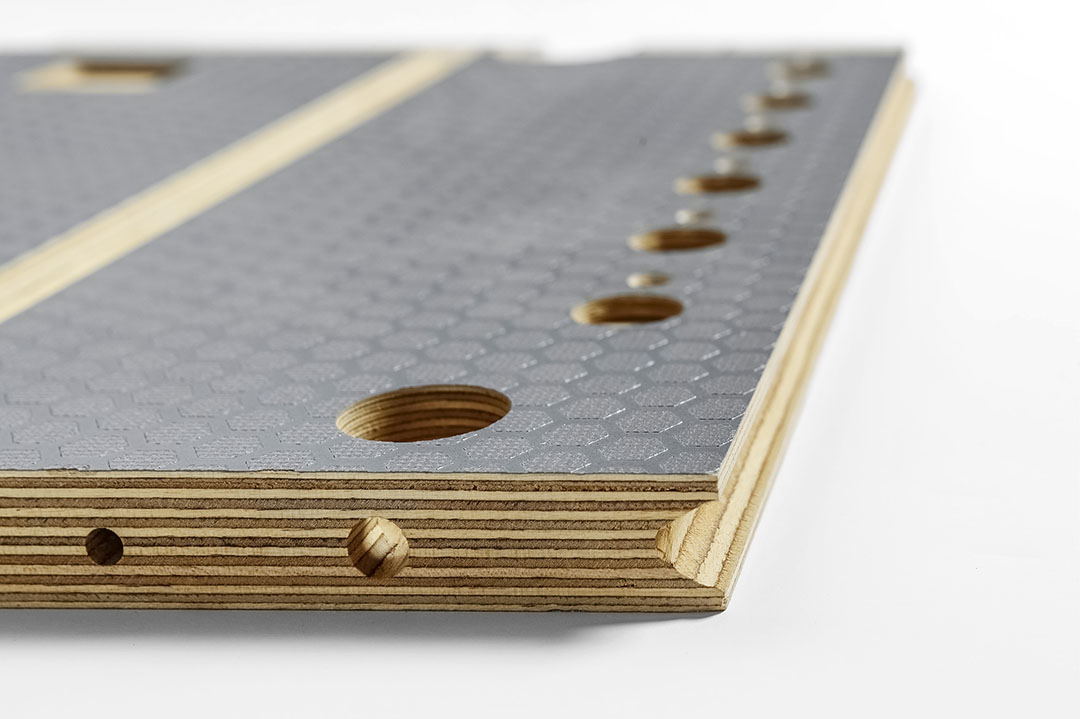

One of the most effective ways to contribute to reducing CO₂ in the atmosphere through our actions and choices is to manage forests sustainably and use long-life wood products. The longer a wooden product is used, the longer the CO₂ released from forestry is not returned to the atmosphere. Birch plywood products manufactured by Latvijas Finieris last a long time and can be reused. Wood by-products from the production process also become raw materials for other long-lasting products and materials, storing CO₂ for the lifetime of the product.

Having weighed up the ecological, economic and social benefits, Latvijas Finieris made a strategic decision more than 15 years ago to use wood products as much as possible in the construction of new industrial buildings. Since then, two development phases of RSEZ SIA Verems, a plywood production workshop at Kohila Vineer in Estonia, and an impregnation workshop at the Chemical Products Plant in Bolderāja, as well as a number of smaller-scale construction and renovation projects have been implemented in large-scale glued laminated timber construction solutions. The latest example is the Furniers warehouse building, which was opened in summer 2022. Latvijas Finieriscamping area Abragciems is also a good example of the versatility of wood use and serves as a unique laboratory for the real environment of birch plywood products.