Latvijas Finieris is starting the construction of a new resin mill with the placement of messages in the foundations

15.01.2025

In order to develop the production of new synthetic resins based on the natural wood component lignin, thus reducing the share of fossil raw materials in the production of phenolic formaldehyde resins, which are currently widely used in the production of furniture, flooring, thermal insulation, sandpaper and many other everyday products, Latvijas Finieris Group started the construction of a new mill in Riga, Bolderāja. The new resin mill is being developed on the territory of Latvijas Finieris AS at Finiera iela 6, Riga. The mill will have an annual production capacity of 45 000 tonnes.

On 15 January, in the presence of government representatives and international partners, the start of construction was marked by the laying of a capsule with messages for future generations in the foundations of the new mill building.

“With the new mill and the VIOBOND project, we are not only contributing to the competitiveness of Latvian industry but also to the transition to renewable resources. The use of lignin in the production of synthetic resins is an important step towards reducing the use of fossil raw materials while creating products with high added value. No to oil, yes to wood!

In addition, given the fact that one of our strategic focus areas is increasingly close cooperation with scientific institutions, this mill and project is a bio-innovation hub, combining research and production to create sustainable solutions for future generations,”says Jānis Ciems, Chairman of the Board of Latvijas Finieris AS.

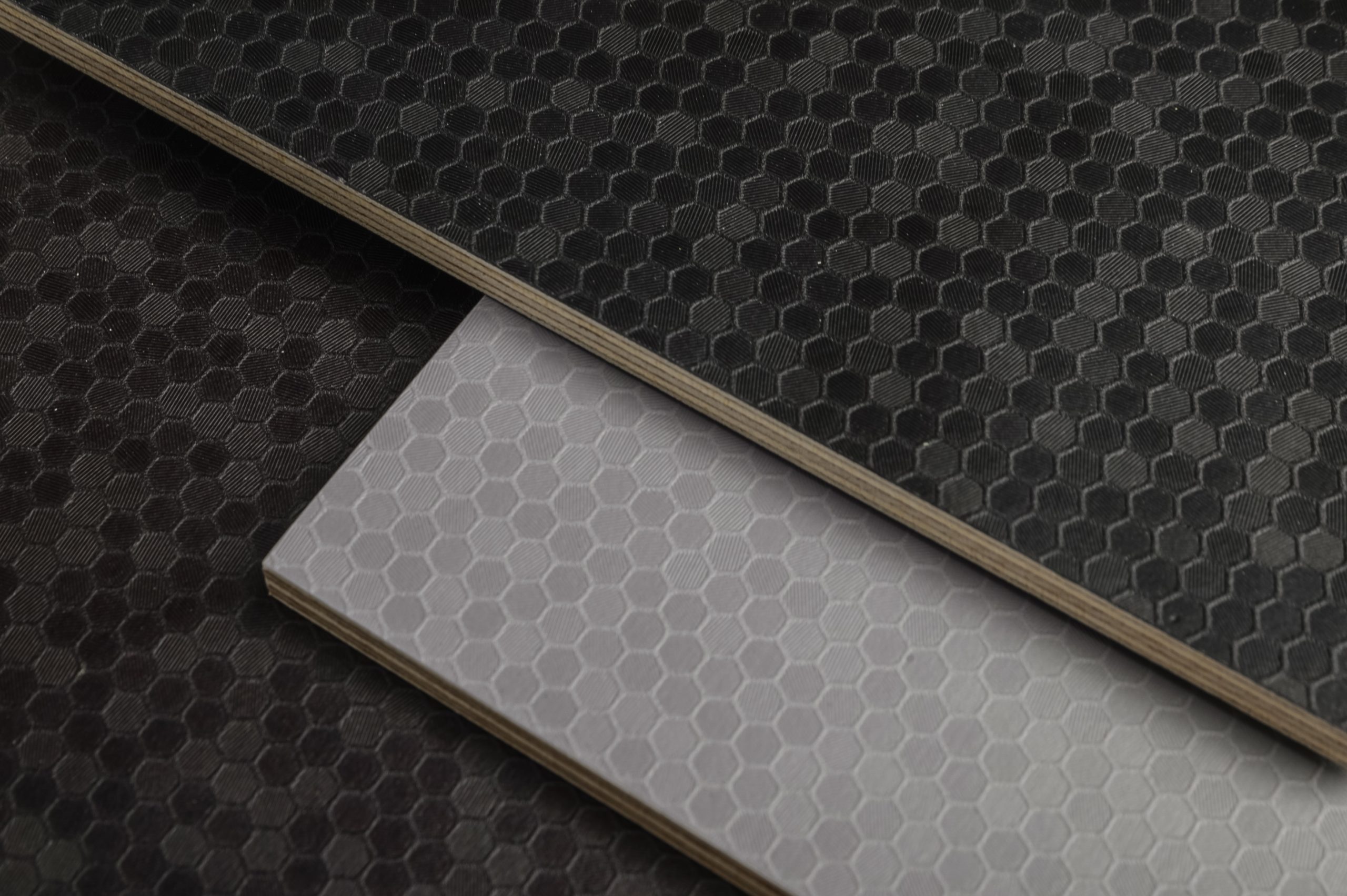

Latvijas Finieris has developed an adhesive for birch plywood production in which lignin partially replaces phenol, and Riga ECOlogical birch plywood products have been available on the market for several years. Further research and construction of the mill is a continuation of the work carried out over many years. With the construction of a new synthetic resin mill, this experience will be scaled up to an industrial level. As a result, it will be possible to provide environmentally friendlier lignin-phenol-formaldehyde resins to all the plywood products of Latvijas Finieris.

“True sustainability is where solutions add value and responsibly create new products, not limit them. The international research consortium project VIOBOND is where I see sustainability and the economy interacting in a meaningful and forward-looking way. I am particularly proud of the fact that eight partners from five EU Member States have been brought together by the leadership and experience of Latvijas Finieris AS,”

said Armands Krauze, Minister of Agriculture, in his address to the audience.

And Kaspars Melnis, Minister of Climate and Energy, said:

“Our decisions today shape all our tomorrows. It is a cycle of cause and effect that starts with a simple truth – you reap what you sow. By cultivating renewable resources and using them efficiently and sustainably, we are building a much better future. By reducing our dependence on fossil fuels, we are becoming self-sufficient. By being careful with our resources, we become more efficient and create a better future for us all.

New knowledge-based technologies that make Latvia independent from imported resources are a way to strengthen our economic potential, build muscle in export markets and gain a competitive advantage.

I hope that the “bacillus” of the sustainability challenge of Latvijas Finieris will be highly contagious and we will hear more and more from Latvian companies and their partners about unique solutions that will work on a global scale in the future.”

Jurģis Miezainis, Parliamentary Secretary at the Ministry of Economics, said:

“Latvia’s wealth and advantages in the world have always been linked to our natural products, which we have always known how to use sustainably, always striving for perfection with a deep respect for what nature gives us. The bioeconomy is our advantage in the world! Knowledge and experience accumulated over centuries is our advantage in the world! Latvijas Finieris is one of the pioneers who did not take the easy way out but acted in such a way that local products are more widely used, have more value and develop our Latvian economy – with new innovation-driven quality.”

The construction of the mill is part of the international research consortium project VIOBOND, which brings together eight partners from five European Union Member States under the leadership of Latvijas Finieris. The main objective of VIOBOND is to develop the use of the natural polymer lignin in high added-value products, partially or fully replacing fossil phenol, a product of oil refining, with this renewable raw material.

“Today, we mark an important milestone in Europe’s shift towards sustainable production and consumption, especially in the construction sector. The innovative bio-based resins to be produced in the future VIOBOND mill will provide safer and more sustainable building and interior design materials with a significant positive impact on consumer welfare. This project will also significantly increase the value of lignin, boosting local economies and innovative circular industrial solutions in the Baltic region,”

said Virginia Puzzolo, Head of the Circular Bio-based Europe Joint Undertaking (CBE JU) Programme Unit, addressing the audience.

The total research cost of the VIOBOND project is EUR 32 million, of which EUR 16 million is a grant from the European Commission’s Horizon 2020 research and innovation investment programme, with the rest coming from the companies involved in the project.

To implement the project, Latvijas Finieris will carry out research amounting to EUR 16 million, of which EUR 8 million is co-funded by Horizon Europe. The total investment by Latvijas Finieris to build the mill is around EUR 40 million.

The new resin mill is being designed by UPB Projekti and built by UPB Energy.

“This is a complex project where technology is key – both the form of the building and the construction process itself are adapted to its requirements. The project requires close collaboration between all parties involved to ensure the seamless integration of technological solutions. The next stage will involve the assembly of the building structures, which will be carried out in parallel with the installation works,”

says Dainis Bērziņš, Chairman of the Board of UPB AS.

Construction of the mill is scheduled to be completed by spring 2026.

It should be noted that in addition to the new resin mill, Latvijas Finieris is also implementing the following investment and development projects:

- Development of the Zābaki tree nursery: a unique complex of wooden buildings and a seedling cooler (to be completed in the first half of 2025)

- Expansion of the VEREMS mill (to be completed in the second half of 2025)

You can learn more about the "VIOBOND" project by watching the video.