From cutting-to-size to assembly of panels with complimentary materials – tailored birch plywood solutions that fit customers’ needs

22.12.2022

Birch plywood itself is a versatile material celebrated in many industries, starting from the DIY sector to massive infrastructure developers. Each industry requires specific technical solutions and that’s where Latvijas Finieris and Riga Wood teams step in by combining needs of customers and trends in the market with service and product development.

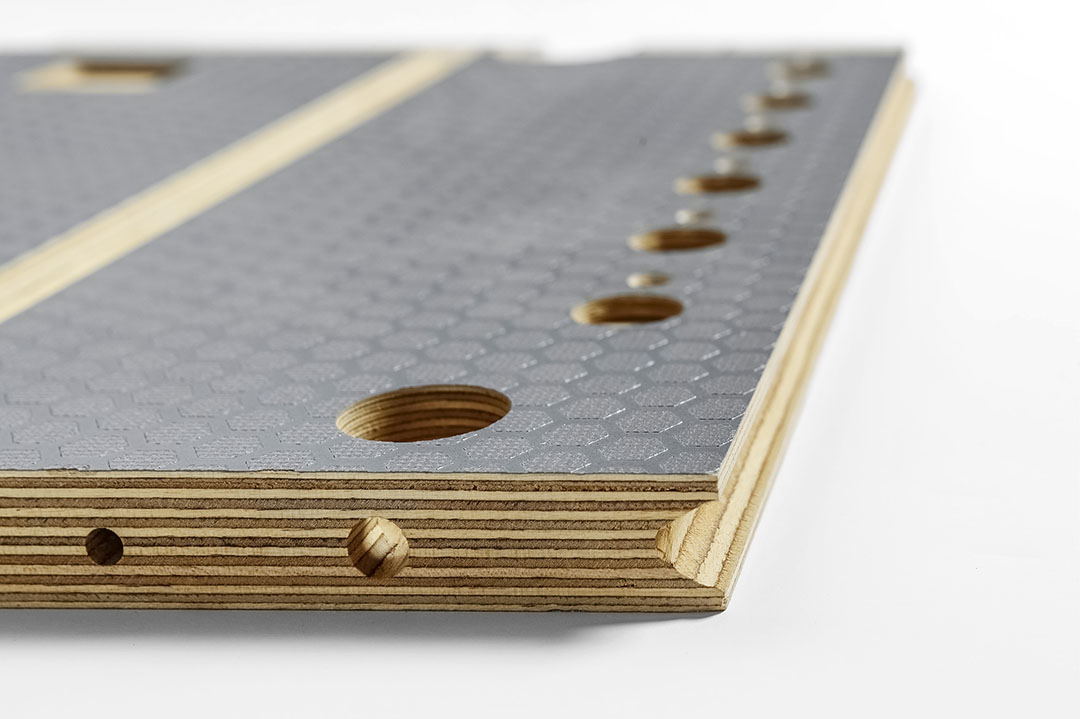

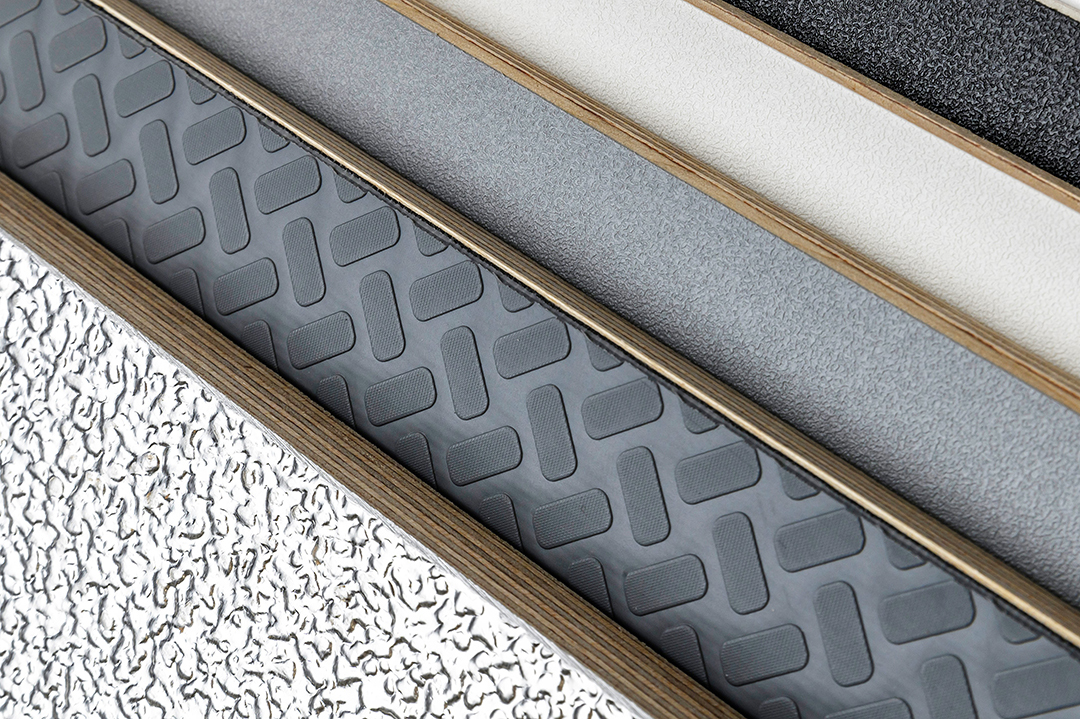

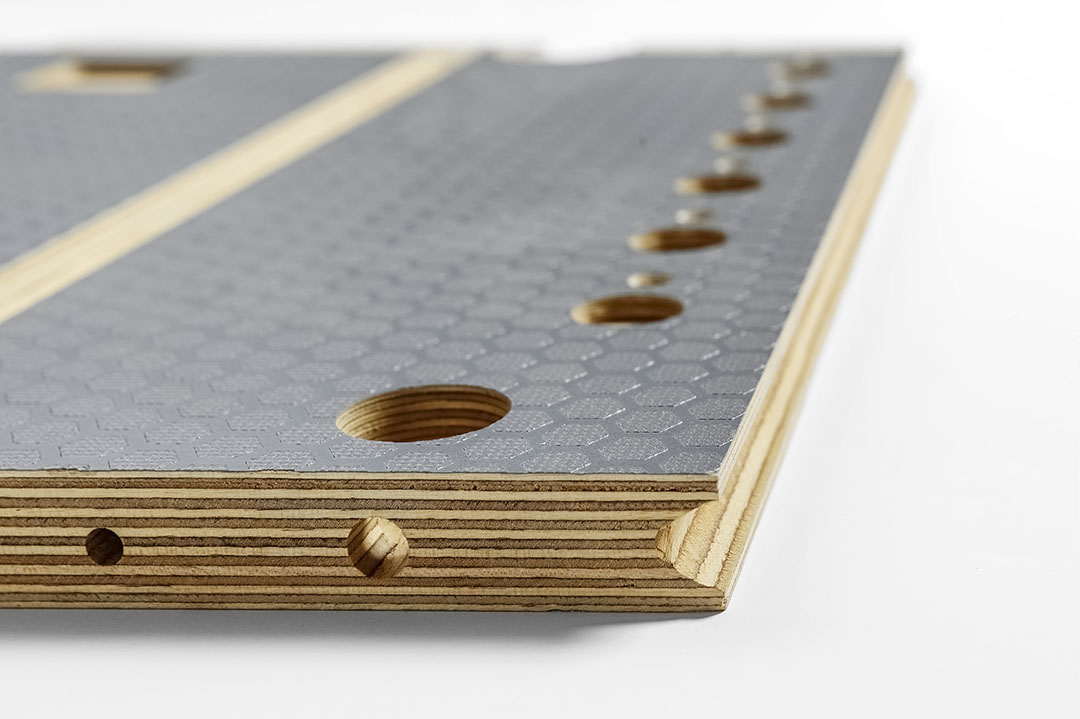

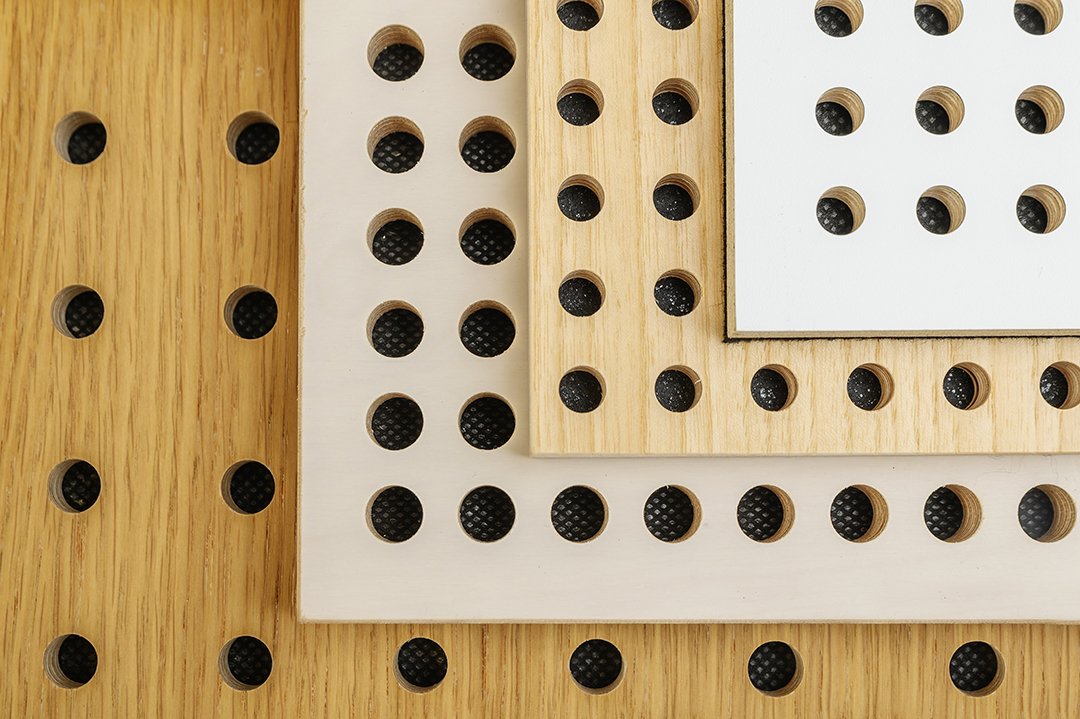

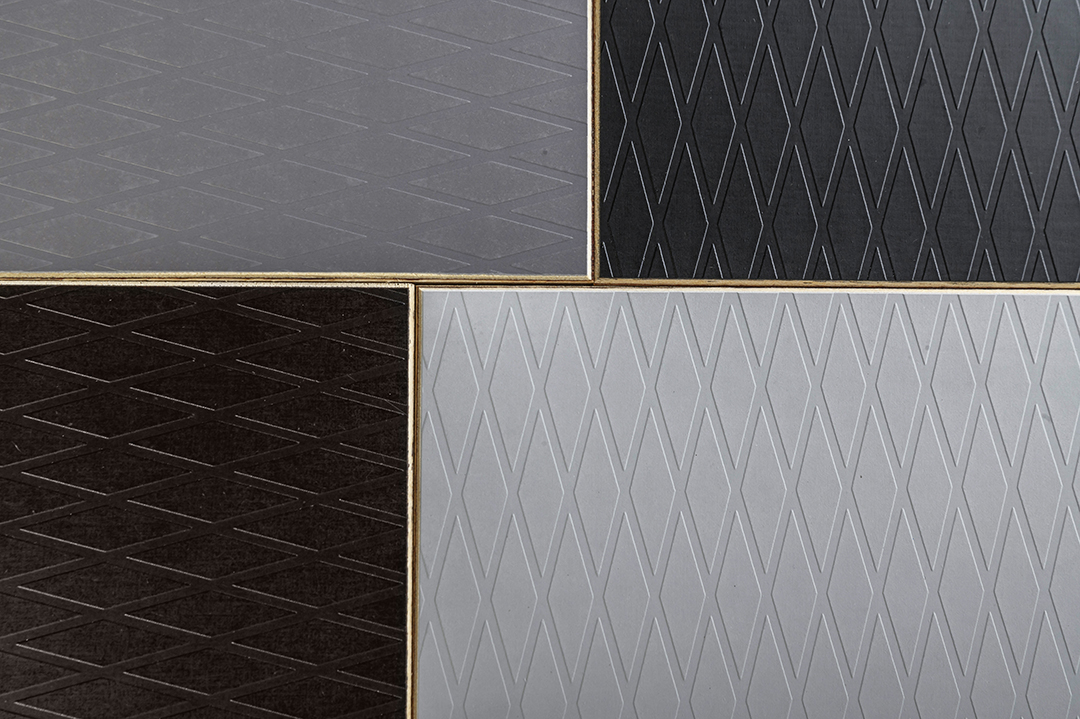

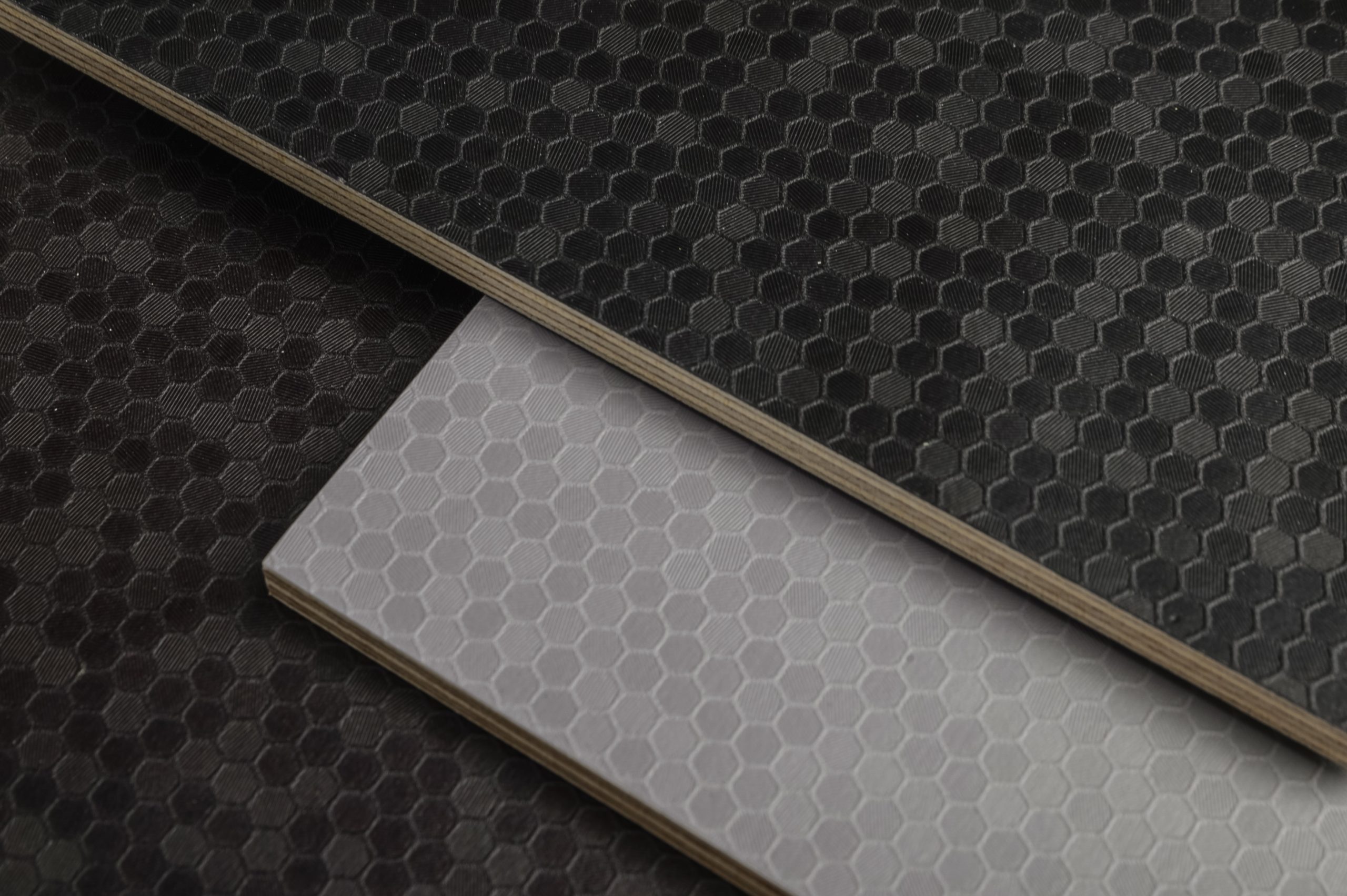

As the saying goes, it’s the little details that are vital. Our tailored birch plywood solutions can be divided into 2 groups – machining and finishing options. Each of them are a part of excellent end-use products. Either cut-to-size, CNC-machining, or edge-machining, due to superb machinability properties, Riga Wood birch plywood products can be further processed with high accuracy. Meanwhile, the surface finishing highly depends on the end use. It can improve specific properties of the birch plywood, turning it into superb products with a decorative, highly durable or impact resistant appearance.

In addition to machining and finishing, our customer needs are met by individual solutions regarding printing, set assembling or composite structures. Further processing allows preparation of ready-for-use birch plywood products, therefore saving customers’ time and resources.

For full information on machining and finishing options, please see the brochure: