Riga ECOlogical

Doing our part for the planet

Green breakthrough in Riga Wood plywood gluing technology

Bio-based and renewable lignin

Riga ECOlogical is our technological breakthrough in green gluing solutions. Bio-based and renewable lignin is used as a replacement for traditional fossil products, creating a safer environment for life and work. Lignin is a recyclable and ecologically friendly product, abundantly available in the entire world in trees and plants.

Test results

Industrial test results show that when using Riga ECOlogical resin, the technical properties of the plywood remain unchanged, while the carbon footprint is significantly reduced from production to the end consumer.

Main features of Riga ECOlogical

Renewable, natural and safe

Stable cost structure

High performance and consistent quality

Traceability

Innovation & development

For better quality of life

Sustainability

Volatile organic compounds

Reduced formaldehyde emissions

BREEAM and LEED

What is lignin?

Lignin is a recyclable and ecologically friendly product, abundantly available in the entire world in trees and plants. All woods contain 20–30 % lignin which, together with cellulose, forms the woody cell walls of trees and binds together the wood fibers and cells. This strong and rigid structure allows the trees to stand and grow upright.

Industrial lignin is usually extracted from wood as a powderous by-product in chemical “Kraft” Pulp production. Even until the 2000s, the primary use of lignin has been energy production by burning, with calorific values comparable to carbon. In Riga Wood plywood, lignin is now bonding numerous veneer layers.

This trend of bioeconomy has a very promising future and Riga ECOlogical is one of the products that proves it.

Improved environmental performance

Riga ECOlogical improves the key environmental indicators of Riga Wood birch plywood from production to final end-use application.

Potential environmental impact has decreased by up to

Including Global warming potential environmental impact has fallen by

Bio-based kraft lignin

Reduced formaldehyde emissions

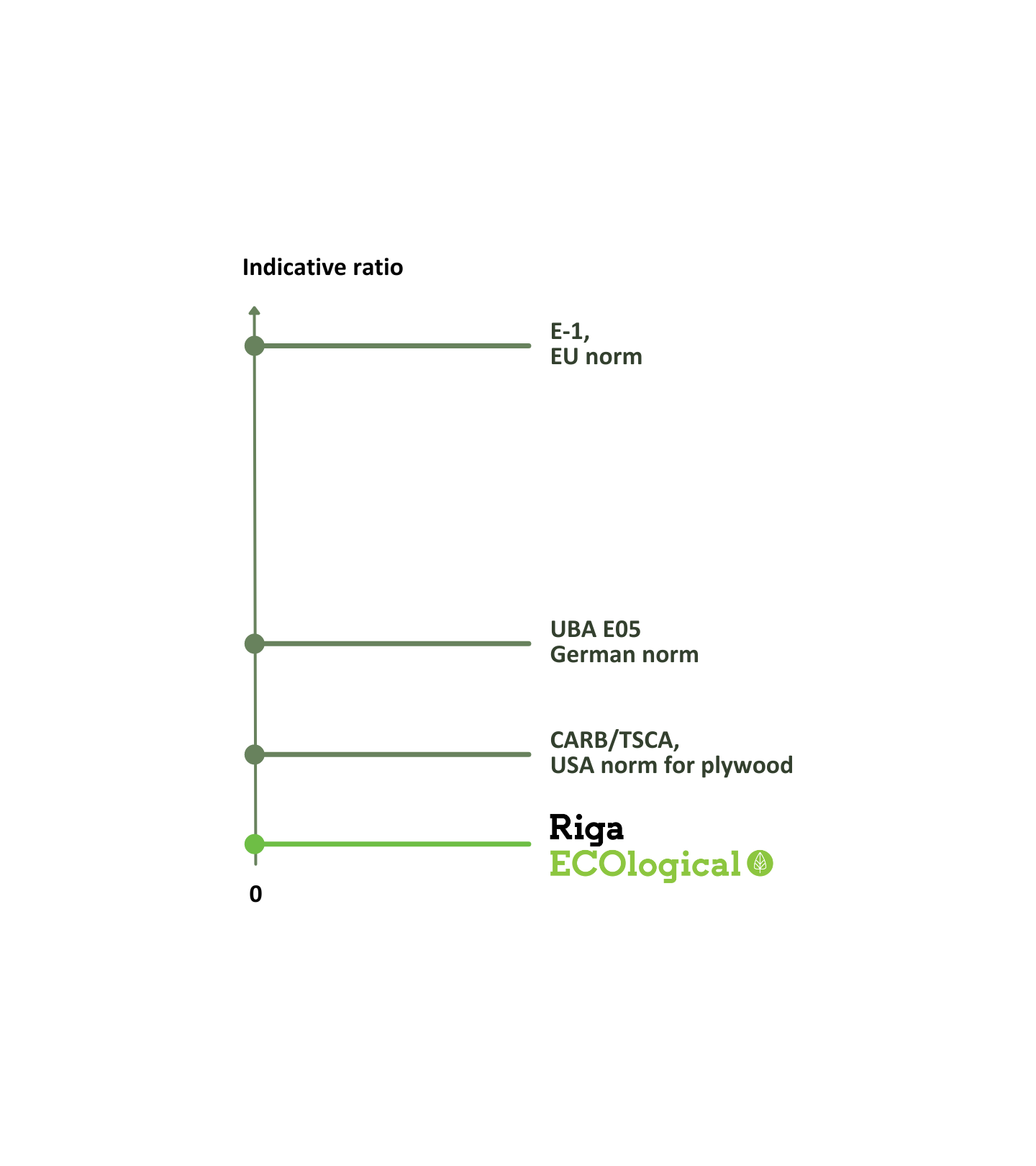

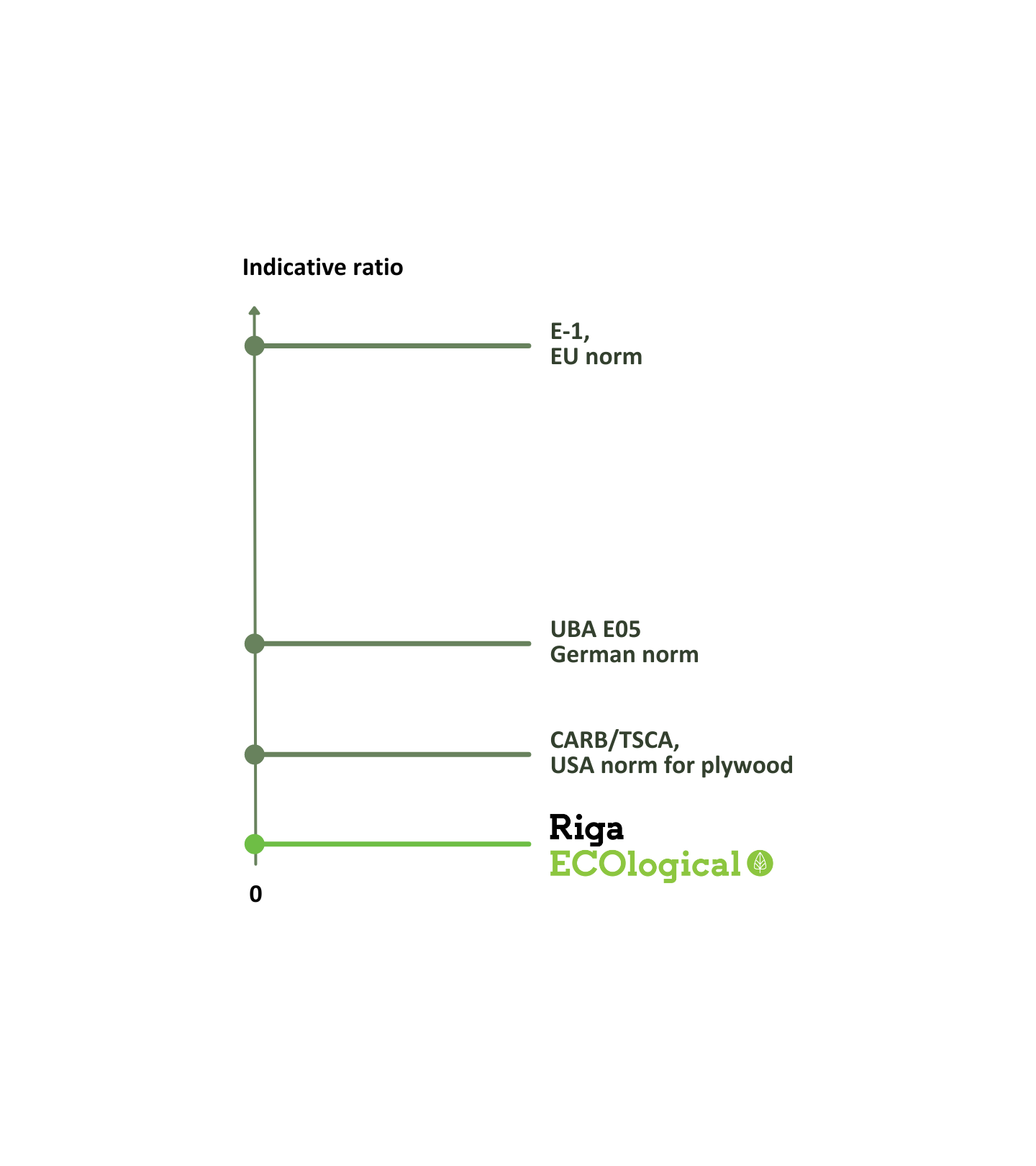

The formaldehyde emission level of Riga ECOlogical plywood is notably below CARB/TSCA USA, UBA E05 German, as well as E-1 EU norms.

FAQs

Does the panel bonded with eco/bio adhesive still pass the exterior bonding tests?

Yes. The panels bonded with the Riga ECOlogical adhesive fully comply with the requirements for exterior (EN 314-2, Class 3) bonding quality.

Does the use of eco/bio adhesive have any impact on the DOP (Declaration of Performance)?

No, the use of the Riga ECOlogical adhesive does not affect the Declaration of Performance (DoP) values of the product. The plywood bonded with the lignin-phenol-formaldehyde (LPF) resin meets the same performance criteria and classification as panels bonded with conventional phenol-formaldehyde adhesive, ensuring full conformity with EN 13986, including formaldehyde emissions and EN 636-3 S (structural use) and EN 636-3 NS (non-structural use) requirements.

Has any long-term testing been performed on the eco/bio adhesive bond?

There are no specific standardised long-term tests designed to evaluate adhesive bond durability over extended periods. Instead, the durability of plywood bonding is assessed through accelerated ageing tests, such as the wet and boiling tests defined in EN 314-1 and EN 314-2, which simulate long-term exposure to moisture and temperature variations. No additional long-term testing has been performed beyond these standard procedures. However, since the Riga ECOlogical adhesive is a modification of a conventional phenol-formaldehyde (PF) system, its long-term stability is comparable to that of standard exterior-grade plywood. Phenolic adhesives are well known for their excellent ageing resistance, thermal stability, and durability under variable environmental conditions. In addition, LPF resin systems have been used in our production for several years, and their performance has consistently proven reliable in both laboratory and real-life applications.