Riga Paint

Riga Paint

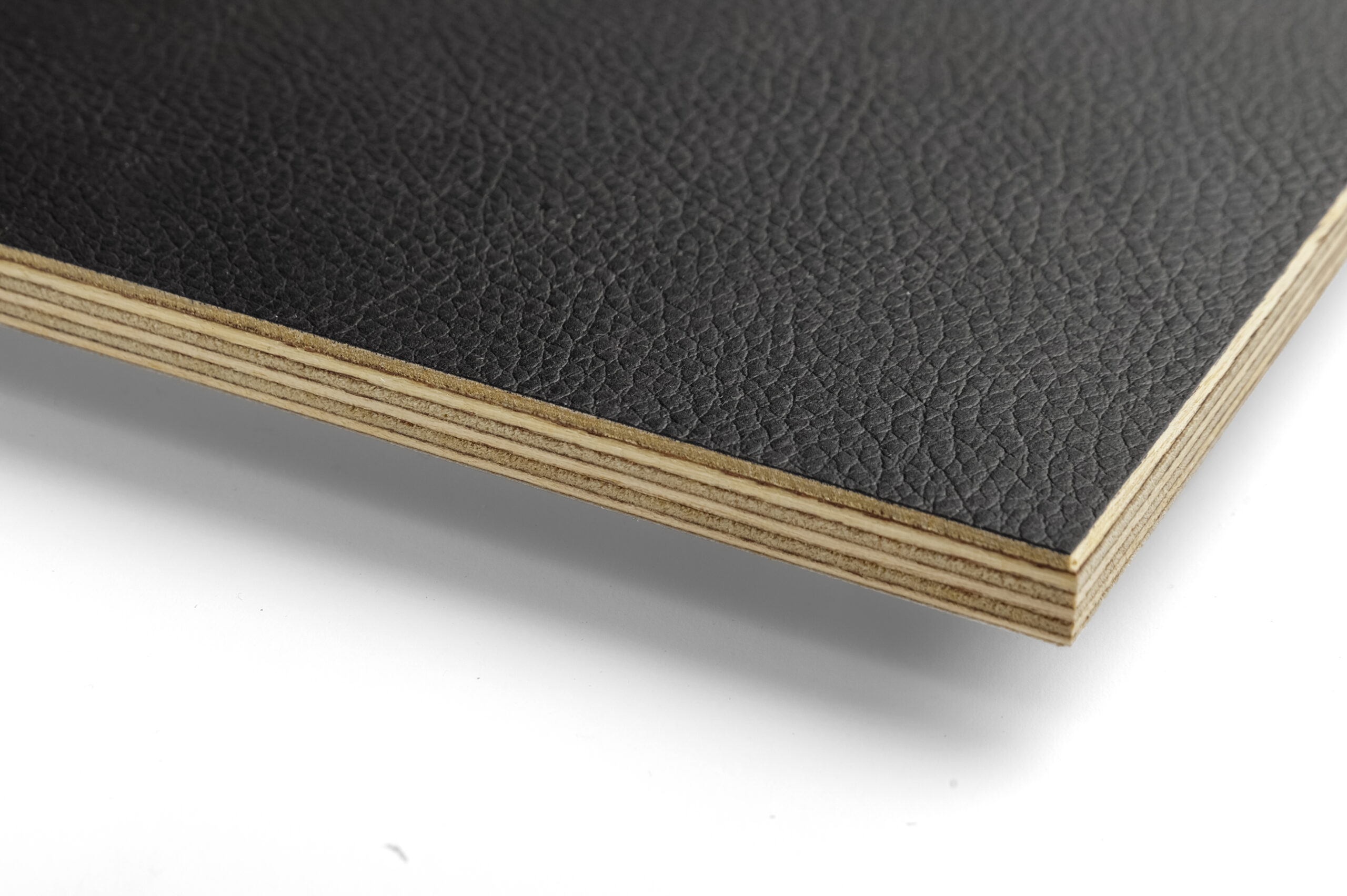

Riga Paint is birch throughout plywood, designed for long-lasting and easy painting. Riga Paint is overlaid with a painting film for further priming or painting.

Application

- Light building

- Road transport

- Sea transport

- Wholesale & Distribution

Major Advantages

- Ensures a solid and crack resistant base for painting

- Ready-to-paint with final coating surface

- Suitable both for interior and exterior applications

- Quick and easy to paint whilst reducing paint consumption

- Suitable for most commercial paint types

- Outstanding paint adhesion with even paint finish

- Sustainable product with long life span

Color

Light Brown

brown, film weight 215 g/m²

Further Processing

- Panels can be further processed according to customer's specification with: cut-to-size, CNC, drilling, milling, jointing, edge machining, assembling in sets, and scarf jointing.

Surface Properties

- The surface is homogeneous and even, paint consumption is reduced and paint cracking avoided.

Sizes

- 1220 / 1250 mm × 2440 / 2500 / 2745 / 2750 / 3000 / 3050 / 3340 / 3660 mm

- 1500 / 1525 mm × 2440 / 2500 / 2745 / 2750 / 3000 / 3050 / 3340 / 3660 mm

- 2440 / 2500 mm × 1220 / 1250 mm

Standard Thicknesses

- 6.5, 9, 12, 15, 18, 21, 24, 27, 30, 35, 40, 45, 50 mm

Certificates and brochures

Product information

Certifications and declarations

FSC certificate

English