Services with added value

The highest quality Riga Wood birch plywood products and related services have been developed with a focus on customer convenience.

Various bespoke solutions and processing options highlight the technical and visual characteristics of Riga Wood’s birch plywood, allowing it to be tailored to the needs of industries and customers.

Individual approach

Certificates and declarations

Additional product quality testing

Customised thicknesses and tolerances

Special product treatment with preservatives

Customised constructions and components

Logistics and delivery solutions

To ensure delivery, we employ both road and sea transportation methods, carefully selecting the most efficient and appropriate solution for each customer’s needs.

Ensured by using road transport:

- precise arrival and unloading date and time at the customer’s specified address

- unloading the shipment at multiple locations

- partial load deliveries

Ensured by using sea transportation:

- transporting the order from the port of unloading to the customer’s specified inland address

Processing options

Cutting to size

Edge machining

CNC machining

Scarf jointed panels and special sizes

Milling and drilling

3D panels

Decorative finishing

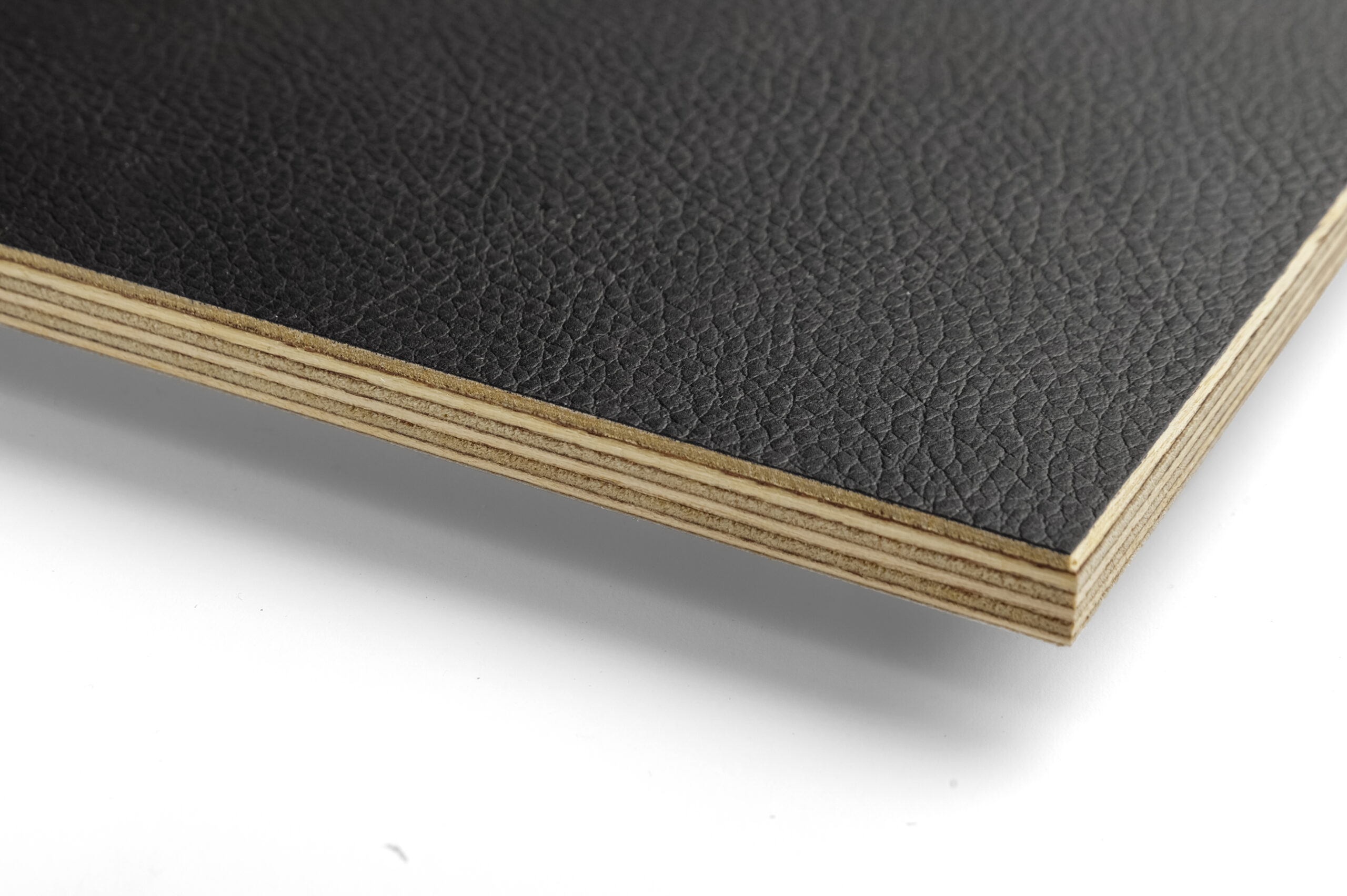

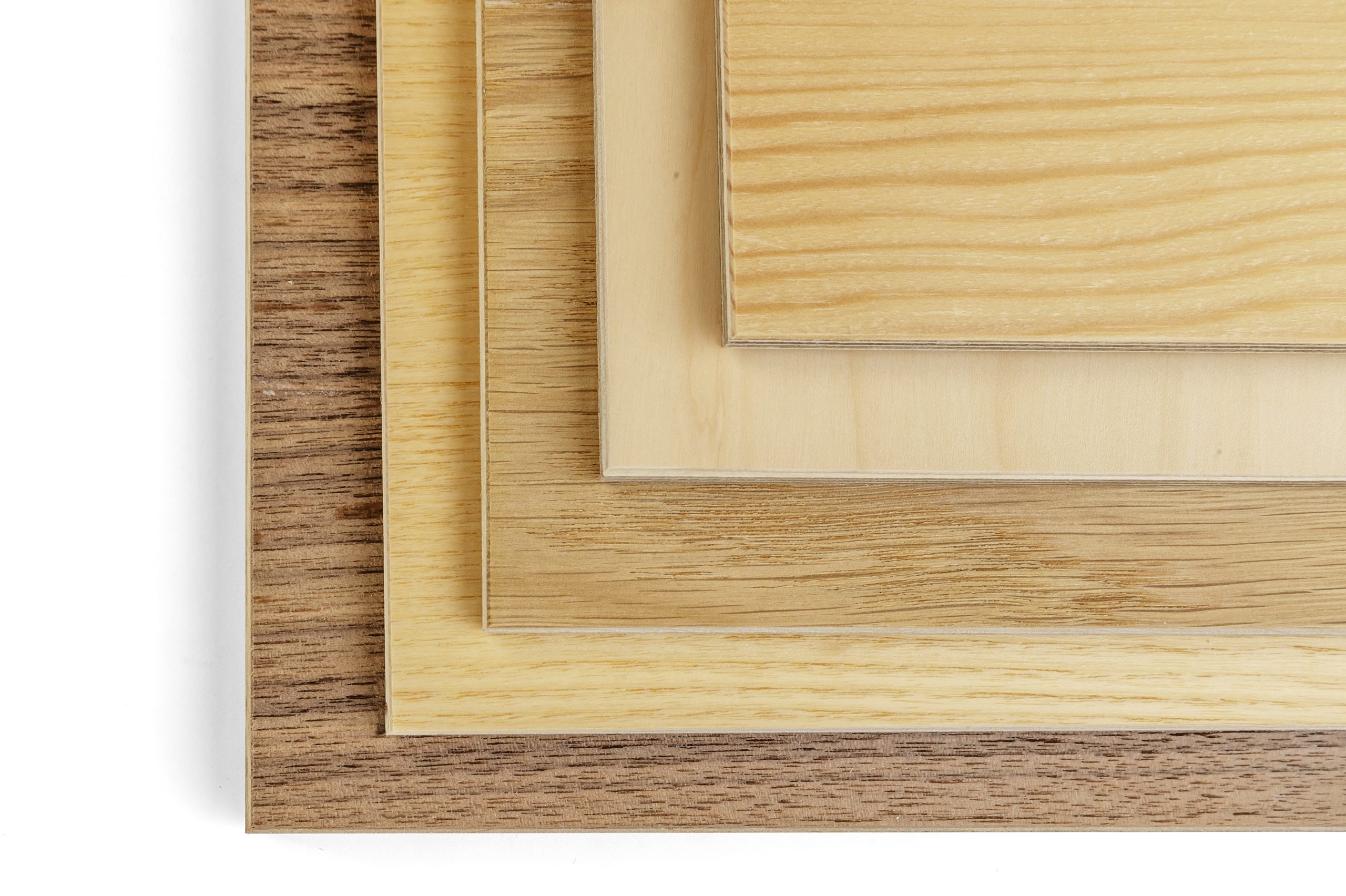

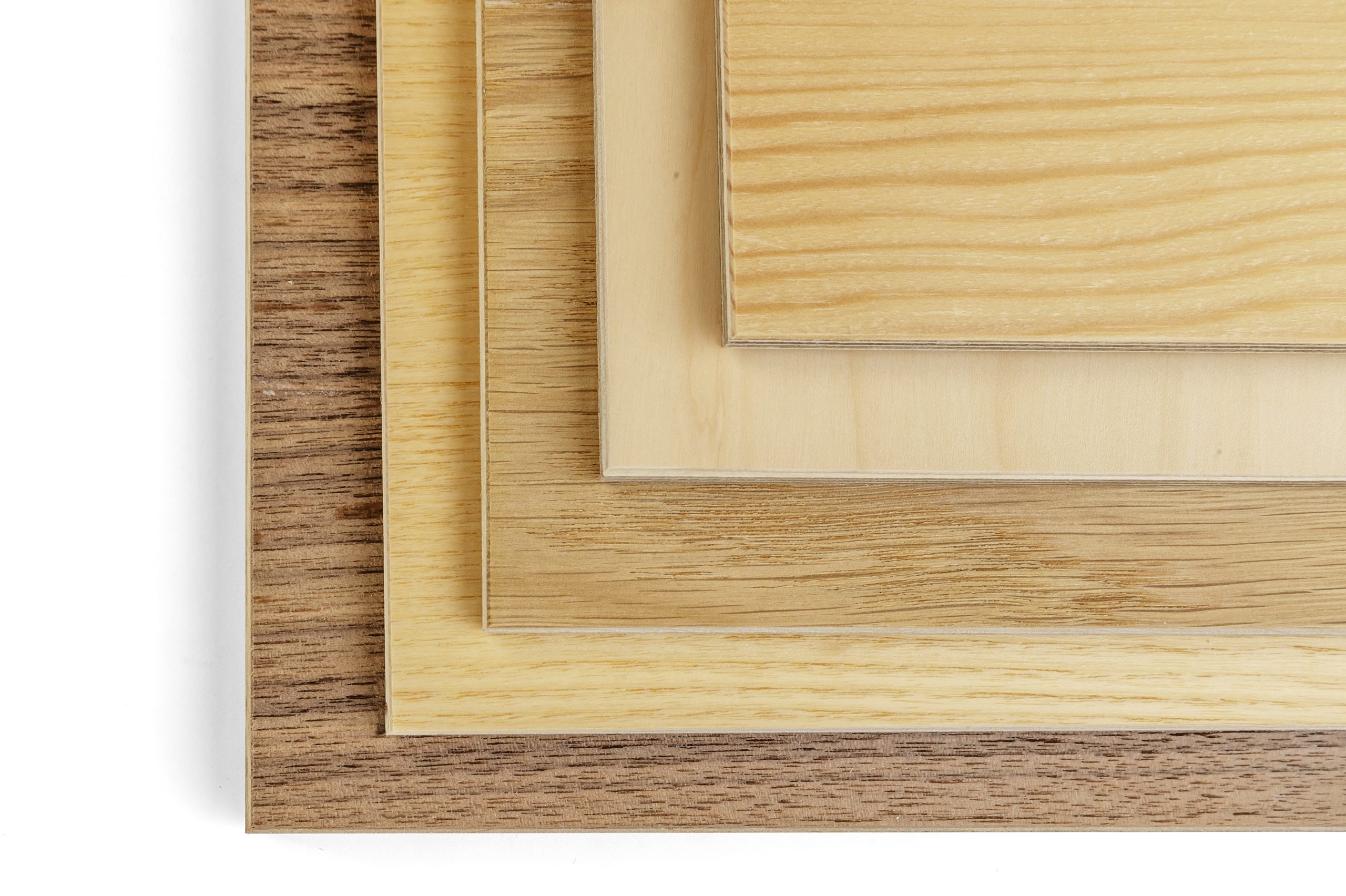

A variety of decorative coatings allow combining the technological properties of birch plywood with a decorative function. Riga Wood birch plywood can be finished with decorative boards of other tree species, such as oak or ash veneer, or imitate leather, stone and other materials. These solutions are especially suitable for industries where the technical properties of birch plywood are essential and at the same time it is necessary to perform a decorative function.

Various plywood processing options are available:

- Priming with UV curing (UV) or polyurethane (PU) primer

- Painting with acid curing (AC), polyurethane (PU) or water-based (WB) paints

- Varnishing with nitrocellulose (NC), acid curing (AC) or polyurethane (PU) varnishes

- Staining with water-based stains

- Surface impregnation with various wood protection products

- Screen printing (logo, product name, code, etc.) with moisture-resistant colours

- The finishing line can also be used for individual operations, for example only for grinding or priming of workpieces.

- Finishing of products of complex shape and larger format and use of non-standard finishing materials are also possible.

Product and service development in partnership with customers

New product development

Our sales, customer service, and research and product development teams are motivated by customer needs and market trends. Utilising state-of-the-art scientific methods, we innovate, develop and enhance our products.

We welcome collaboration with customers in the advancement of new birch plywood products. By merging the expertise of our specialists with the industry leaders’ experience, we foster the development of optimal solutions that align with the intended product applications and industry standards.

Consultations and technical support

Our experts offer personalised consultations regarding the technical features of the product, its performance and the most appropriate solutions tailored to the specific industry and project. We also offer the option for on-site advisory support.

Recognising the unique needs of each industry, we customise our service offerings to facilitate swift and precise information exchange, as well as efficient logistics solutions.

Certificates and declarations

Other documentation not mentioned on the list can be prepared on request by contacting a regional sales office.